Did you know MAGNIVA® Platinum can also be a good inoculant choice for wholecrop cereal silage, grass silage and lucerne silage too?

In the past many inoculant suppliers have talked about a “grass inoculant” and a “maize inoculant”, however this does not acknowledge the specific challenge that is occurring with each silage crop.

MAGNIVA® Platinum is designed for silages that are prone to heating. Heating silage not only loses nutrients (feed and ME are literally lost into the atmosphere as heat), it also is at risk of excessive mould growth and mycotoxins. Moulds and mycotoxins are bad for livestock health, and for the digestibility of the whole diet, not just the silage that is spoiled.

What we know is that heating challenges can occur in all forages, if the conditions are right for it. So what conditions increase the risk of heating?

Higher dry matter

The more air in the stack or bale, the more ‘fuel’ there is for yeasts and spoilage microbes. Wholecrop cereal silage also has the challenge of hollow stems which trap more air. Grass or lucerne silage that is >40% DM will struggle to achieve optimal compaction and will trap more air. These types of silages wont have the black, foul smelling spoilage typical of wet silages, but rather will be at risk of musty, white-moulds which are unpalatable and not helpful to the performance of livestock.

Less than ideal compaction

Not everything goes perfectly at harvest time. Due to weather conditions, or simply the fact that harvesting machinery has got so much faster and more efficient, silage can come into a stack site at a rate of knots. This means that compaction can be challenged, which means more air trapped in the stack. As above, this fuels yeasts and moulds and increases the risk of heating.

High starch or sugar crops

Starches and sugars are the perfect ‘food’ source or substrate for yeasts and moulds. This means that crops that have some grain fill (such as wholecrop cereal silage taken at the cheesy-dough stage) present a significant risk for heating. High sugar ryegrasses harvested at a high dry matter may also face a similar challenge. This is an important point to consider, because if a maize or cereal silage is harvested early, when the crop is green or has little grain fill, then this would be the cue to consider switching inoculant to one that focusses on front-end fermentation. In most cases though, maize and wholecrop cereal silage will have a moderate-high level of starch and will require MAGNIVA® Platinum to keep it cooler for longer.

Wide stack faces / slow feed out rate

Often it can take a day or two (or even more) to get across the face of the stack. This is especially the case in very large and wide stack faces, or when the mob size / feed allocation has reduced. The longer the face is exposed, the greater the risk of heating.

Feed mixed up or fed out in advance

For convenience, many farmers mix up feed the night before, or feed out in advance. This means silage can be exposed to air for a reasonable period of time before being consumed by livestock. As above, air exposure = heating risk. This means that thinking ahead to how the silage will be fed is an important consideration at the time of harvest.

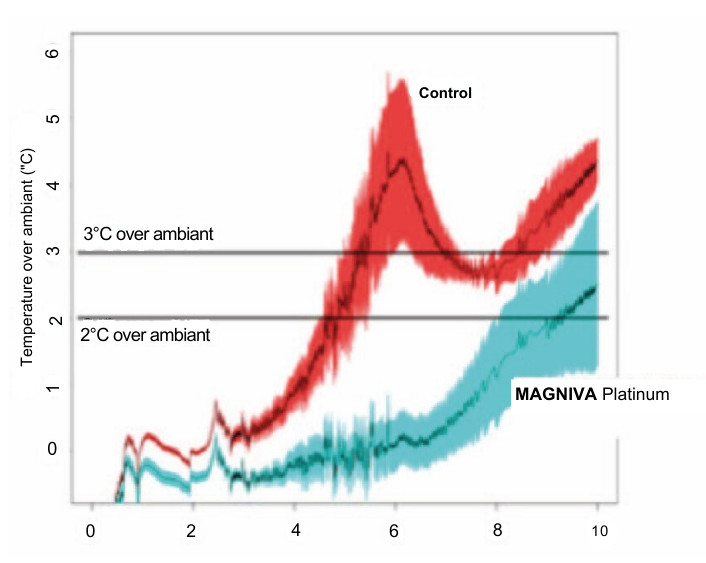

Drouin, P. Tremblay, J Renaud, J. Apper, E. (2020). Control silage starts to heat initially after 4 days. MAGNIVA Platinum Silage stays stable for 8 days after opening. Microbiology Open.

Lastly, the risk of heating can be exacerbated in the top metre of the stack due to the risk of oxygen continuing to enter through the cover. This is why SiloStop® Orange High Oxygen Barrier Film is essential on these stacks. Stopping the entry of new oxygen minimises the yeast and spoilage microbe activity at the surface. By using SiloStop® Orange film you can retain eight percent more silage in the top m3. eight percent retained from a stack with a density of 240kgDM/m3 is 19.2kgDM or 201MJME. So for every metre that you cover with SiloStop® Orange, you are getting 29L of milk or 5kg of meat (beef). That’s an return of $23/m2 (milk) or $15.50/m2 (beef)1. That’s a 10:1 ROI for a dairy farmer or 8:1 if the silage is destined for beef cattle..