Cereals provide tremendous flexibility for silage makers – they can be sown in autumn or spring and can be harvested at a range of growth stages from chopping green at the boot stage (before seed head emergence) to cutting whole crop cereals at the cheesy dough stage (when the cereal grain has the consistency of soft cheese). Cereals have the potential to be ensiled into nutritious palatable silage, which gives a good stock performance.

Crop selection

Oats are more commonly cut at the boot stage and sometimes at the milky dough stage. Barley, wheat and triticale are usually grown to harvest at the cheesy dough stage, but all three can be harvested at the boot stage. At the cheesy dough stage, barley dries down fastest so it only has a narrow window between not quite ready and too dry (in dry conditions, this can be just a few days). Triticale has the widest harvest window and can be a better option where there is less control of time of harvest.

Timing of harvest

Cutting at the boot stage will give higher protein silage with energy from the leaf’s digestibility. Cutting at the cheesy dough stage produces lower protein silage but with good energy coming from starch and more physically effective fibre. Cutting after seed head emergence but before grain fill gives lower energy silage, as the fibre in the straw is less digestible than the leaf and there has not yet been sugar and starch accumulated in the grain.

Additive selection

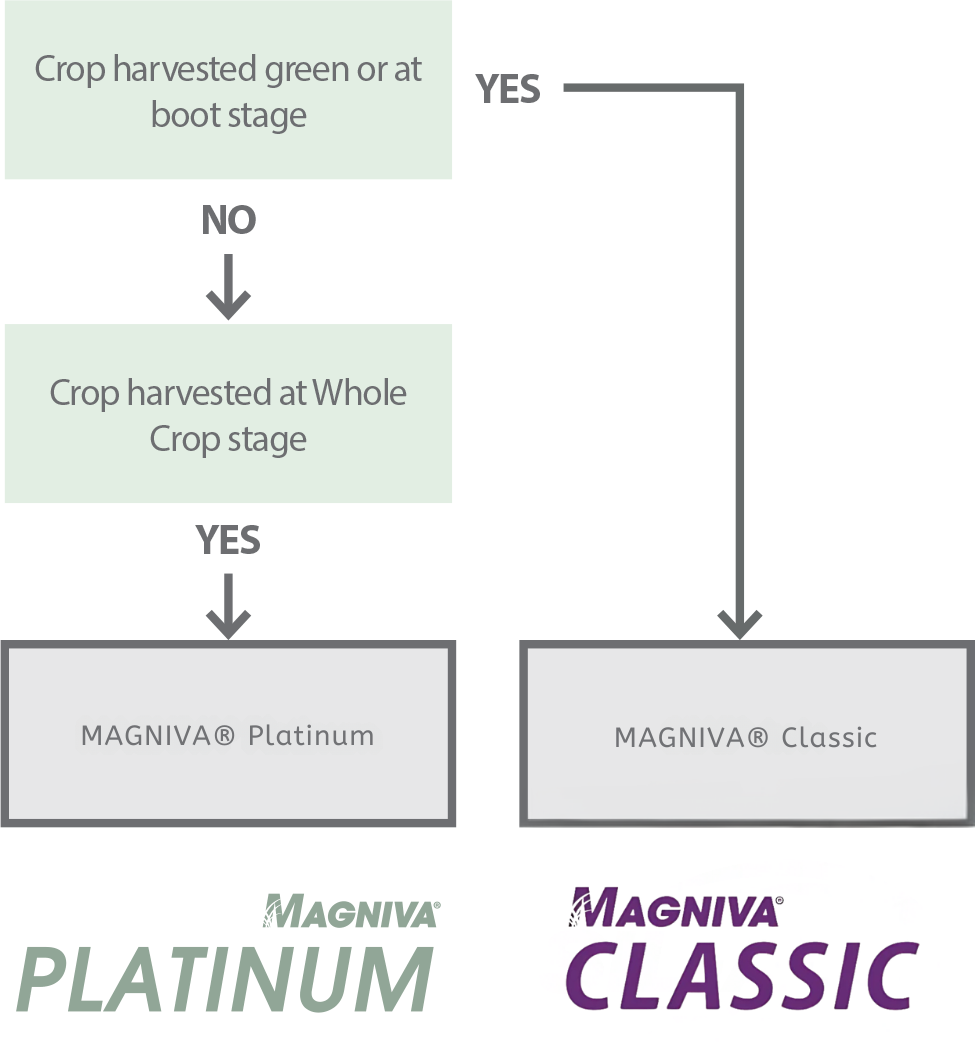

Cereal silage cut at the boot stage usually has a lower dry matter (DM) % and high protein content, requiring more acid production during fermentation. MAGNIVA® Classic contains large numbers of lactic acid bacteria to ensure a fast efficient fermentation, making it ideal for this type of silage.

Cereals cut at the cheesy dough stage naturally ferment quickly, as they have a higher DM%, high starch and low protein content. However, high starch silage is more prone to heating at feed out due to yeast and mould growth. MAGNIVA® Platinum is the most suitable inoculant for whole crop silage as it improves silage stability at feed out.

Nutritech range of inoculants are EU registered and contain known levels of live bacteria, so you can be sure you’re saving the nutritional quality of your crop.

Compaction

Cereal silage cut at the boot stage must be wilted before ensiling to avoid silage effluent (leachate). For pits and stacks, ensiling at 30-35% ensures no effluent but the crop can still be well compacted. For bales, wilting to 35% ensures good bale shape and compaction.

When cereal plants reach the cheesy dough stage, the plant should be dry enough to direct cut – the target is 38% DM. At this growth, stage plants can be drying fast, and a crop can go from ‘not quite ready to ‘too dry’ in a matter of days, so vigilance is crucial. Once the crop is over 40% DM standing, it can be hard to compact – chopping shorter and packing in thin layers will help. When baling cereals at the cheesy dough stage, it is best to err on the early side and use knives in the baler to help with the compaction. Poorly compacted bales are more likely to go mouldy.

Sealing

As cheesy dough cereal silage is prone to aerobic spoilage (such as caused by yeasts and moulds when air is present), it is important to seal it well to keep the air out once good compaction has been achieved. Using Silostop® oxygen barrier film will reduce aerobic spoilage losses in the top metre which is particularly beneficial for cereal silage. Independent testing has confirmed that Silostop® oxygen barrier film is 60 times more effective than conventional black/white film in preventing oxygen transfer into silage. Re-usable Silostop® Anti-UV Cover can be used on top of Silostop® with gravel bags, removing the need for tyres and reducing the amount of plastic use.

For bales, use at least 6 layers of quality wrap and move wrapped bales either within a day or after they have fermented, to avoid ‘popping’ bales when they are lifted and damaging the integrity of the wrap. Bales should be stored on a suitable free-draining site, stacked no more than 2 high, and not jammed up hard against each other.

Pest control

Whole crop cereal silage is often referred to as a ‘rat magnet’ as it is so attractive to rats and mice. Baiting needs to be done early before the rats and mice are established in the silage. It also helps to spray out the ground around the silage so there is no cover for rodents, particularly along the sides of tubes and ag bags. Birds are also attracted to whole crop cereal silage, they pick out the grains from the exposed silage face and leave the straw. Nets can be used to keep birds off the face.

Feedout management

Once stacks and pits are opened and the silage face is exposed to air, yeasts and moulds can start to grow, resulting in nutrient loss and the risk of mycotoxins. To minimize losses, the removal rate should ensure the face returns at least 30cm daily. Making a narrower, longer stack can help achieve this for lower stock numbers. A block cutter keeps the silage face smooth with minimal air penetration. Using MAGNIVA® Platinum inoculant increases the time that silage can be exposed to air at feed out before it starts to heat.

How good is your silage?

If you want to know how good your silage is, and how you could improve it for next season, then the Nutritech team are well equipped to help. Not only can they help with silage sampling, they also have a range of tools for assessing silage at the stack face or bale.

Silage sampling

When sending a silage sample away for analysis, it is important that it is representative of the silage as a whole, and that it doesn’t deteriorate on the way to the laboratory. This means using specific sampling techniques, and in some cases appropriate tools such as a silage corer. The report that comes back can contain a wealth of useful information and the Nutritech team have the knowledge to help interpret it, and a handout with guidelines to help you understand it yourself.

Dry matter %

A silage laboratory analysis is a reliable way of learning the dry matter (DM) % of silage, and is what should be used for trading forage, but sometimes a quick on the spot estimate can be useful. The Nutritech team have a guide for assessing approximate DM% by hand and for getting a more accurate DM% estimate using a microwave oven. They can also assess DM% using a Koster tester which can take a few hours. Knowing the DM% of silage makes feed budgeting more accurate and ensures stock are getting the correct feed rate on a DM basis.

Silage pH

It is the acids formed during fermentation that preserve the silage crop as a low pH (a measure of acidity) helps prevent the growth of spoilage organisms. Silage pH strips can be used for an on the spot estimate of pH. As silage starts to spoil the pH increases, so checking different areas of a stack face, or the outside and middle of a bale, can indicate whether spoilage is occurring on the outside areas.

Silage density

Achieving good silage density is important for reducing DM losses after ensiling, and for pits and stacks it also helps reduce aerobic losses at feed out. DM density of silage is typically 200 – 250 kgDM/m3, but at the sides of poorly shaped stacks it can be much lower. The Nutritech team have density corers to measure silage density, and they can also calculate it for bales of a known weight by measuring the volume and DM%.

Amount of silage

The amount of silage in a stack or pit can be calculated using length, width and height measurements and using the silage DM density. The Nutritech team can help with this calculation, giving useful information for feed budgeting.

Grain processing and chop length

A measuring cup and Penn State particle separator are useful tools for assessing kernel processing and chop length of maize. Assessing silage in the stack will show whether kernels were well processed and chop length was appropriate for achieving good compaction, but once the silage is made it is too late to change it. These tools are most useful when used to assess the first loads of fresh chopped maize arriving at a stack or pit site, so information can be fed back to the harvester driver and adjustments can be made if needed. If kernels aren’t well processed, they will not be fully digested and stock won’t perform as well.

Assessing aerobic spoilage at feed out

When silage is exposed to air and yeasts and moulds start to grow, they produce heat. The hotter the silage, the greater the spoilage and the faster the digestible nutrients in the silage are disappearing. The Nutritech team have 2 useful tools for assessing aerobic spoilage, a temperature probe and a thermal camera. These will indicate if heating is occurring at the stack face and where, providing useful information for any changes needed in stack face management. Not only does heated silage have lower nutritional value, it also carries a risk of mycotoxins which can harm stock health.

If you would like help in assessing your silage, contact your local Nutritech Area Manager. They are all well equipped for the job and know to help you improve for next season.