Did you know that poorly managed and untreated maize can be subjected to significant losses of nutritional quality and volume? On a dry matter basis there can be 20% or greater losses of silage, which in a time where purchased feed cost is so high, this can have a devastating impact on farm profitability.

Many farmers believe that maize and wholecrop cereal silage will ferment quite adequately naturally, due to the high sugar and starch content and the easy-to-ensile nature of the crop. owever, the advent of new DNA analytical methods such as metagenomics suggests that maize and wholecrop cereal silage is no different than other forages when trying to produce the best quality silage.

Over just a short growing period, the microbial diversity of a standing corn silage can significantly change week to week, and many factors such as weather and field management can play a part.

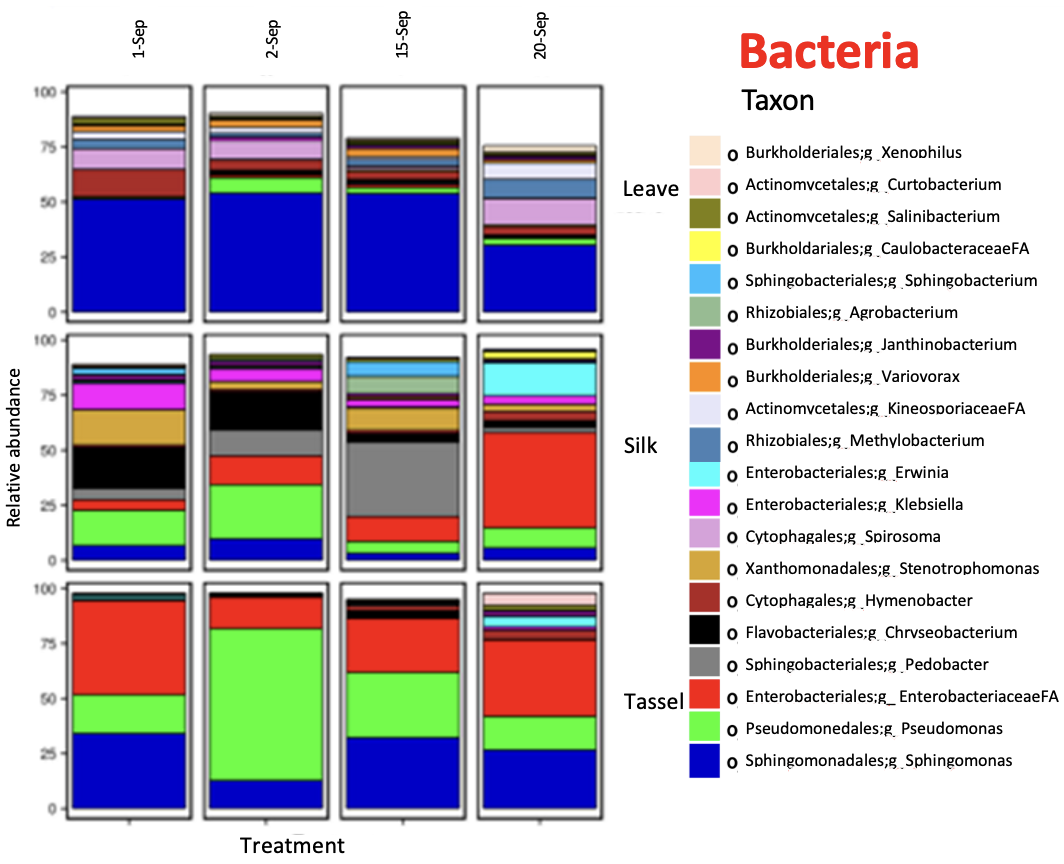

In Figure 1, the different coloured bars represent different types of bacteria in a standing crop of maize. Many of these bacteria can be undesirable with regards to making good quality silage. Therefore, if the silage is not inoculated at harvest, there is a risk that these undesirable bacteria will dominate the fermentation process, resulting in a poorly fermented silage.

Poorly fermented maize and wholecrop cereal silages will have losses both through the ensiling period due to undesirable bacterial growth, and through increased spoilage when the silage is

opened (due to yeast and mould growth in aerobic conditions).

This significantly impacts costs as this lost silage must be replaced with purchased feeds, and the presence of spoiled silage can reduce the digestibility of the whole diet (click to read Don’t Feed Spoiled Silage)

Figure 1: Maize silage, microbial diversity prior to harvest (relative abundance). Drouin, P. Tremblay, J Renaud, J. Apper, E. (2020) Microbiology Open.

The impact of condition specific inoculant

Treating maize or wholecrop cereal silage with a condition specific inoculant will not only maintain the silage quality, but it also reduces silage losses through the fermentation and losses due to instability.

It does so by actively inhibiting the growth of yeasts and moulds. The abundance and types of bacteria found in maize silage change in silage treated with MAGNIVA® Platinum compared to an untreated control over 64 days (Figure 2).

![]()

Figure 2: Succession of bacteria amplicons over 64 days of fermentation. Drouin, P. Tremblay, J Renaud, J. Apper, E. (2020) Microbiology Open

Using new DNA sequencing techniques, we can see how MAGNIVA® Platinum reduces growth of undesirable bacteria through the fermentation of maize silage at 35.5% DM. After 64 days ensiling desirable Lactobacillus (blue bars) accounted for 90% of the total bacterial abundance in the MAGNIVA® silage compared to only 46% in the control.

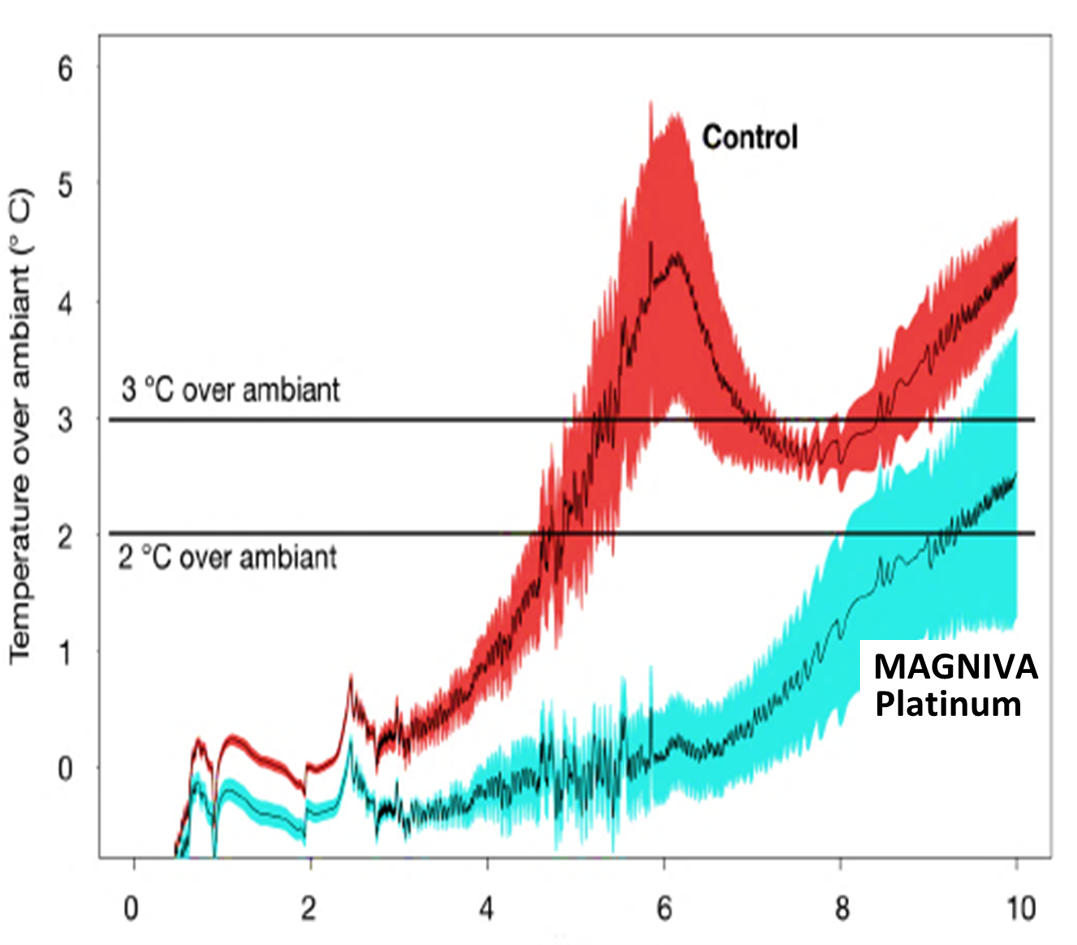

This dominance of desirable bacteria is what helps reduce the risk of heating or spoiling, as shown in Figure 3, where untreated control silage experience significantly more heating than silage treated with MAGNIVA® Platinum. Keeping silage cool is important as heating stacks can lose up to 3.5% of silage on a DM basis per day (Pahlow and Muck, 2009) , which can add up to a significant cost.

Figure 3: Control silage starts to heat initially after 4 days. MAGNIVA Platinum Silage stays stable for 8 days after opening. Drouin, P. Tremblay, J Renaud, J. Apper, E. (2020) Microbiology Open.

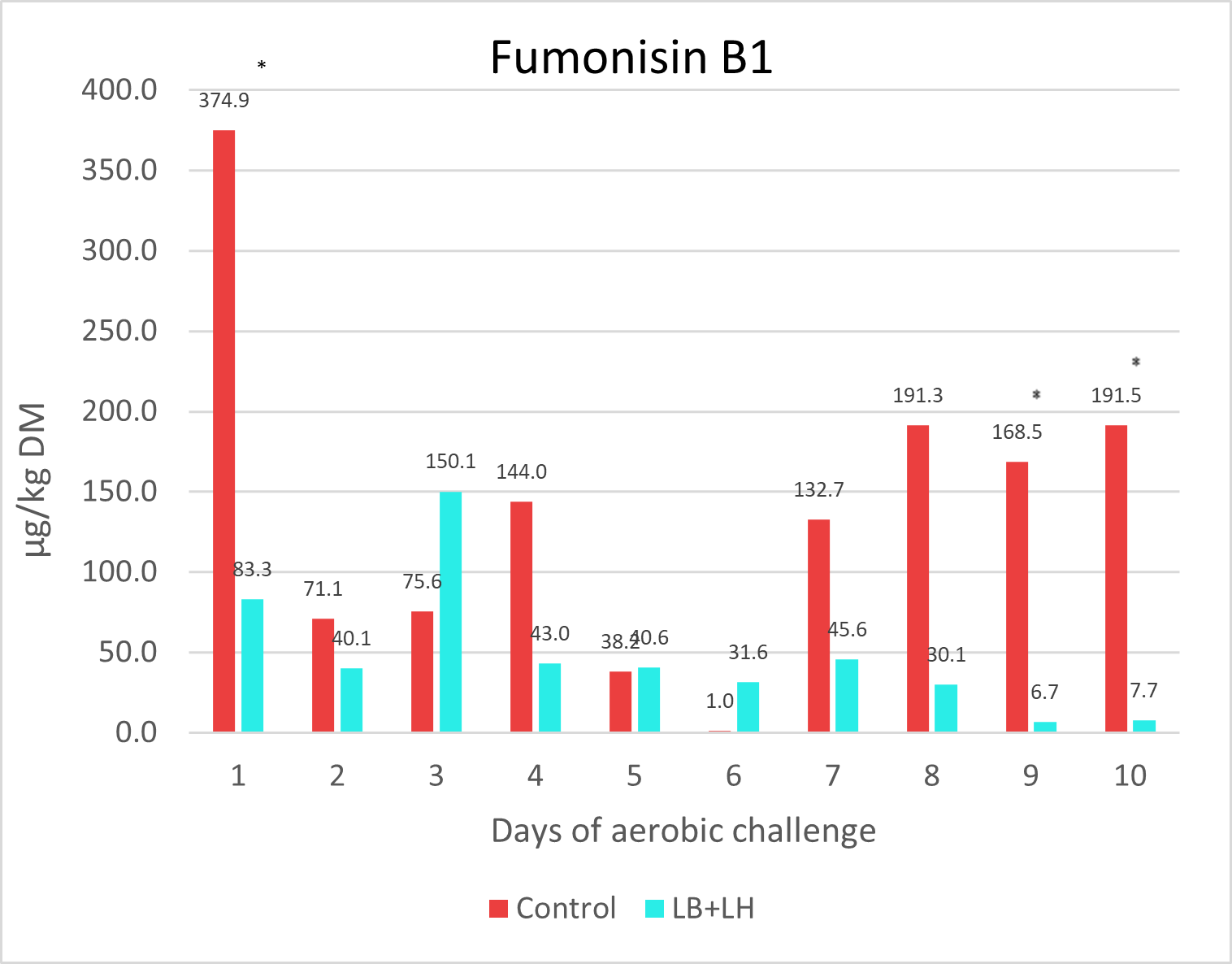

Heating silage also increases the risk of moulds and mycotoxins, which can be detrimental to silage palatability and can cause significant drops in milk production, slips and poor feed conversion efficiency. We know that in silages inoculated with MAGNIVA® Platinum, mycotoxins such as Fumonisin B1 are reduced (Figure 4).

Another advantage of using MAGNIVA® Platinum is that it’s ‘cooling effect’ is begins after just 15 days in the stack, rather than waiting six weeks for inoculant products that rely on L.buchneri alone for aerobic stability.

This early access to hygienic, cool silage is hugely valuable in a season that has seen many farm business use up most of their silage stocks earlier than usual.

So if you haven’t done so already, now is the time to choose your inoculant and have it on hand for your contractor. As we all know, if they don’t have it, they can’t apply it!

Now is also a good time to ensure you have a silage cover and sealing system on farm before harvest starts. The Silostop® range of oxygen barrier films, single-step covers (Silostop® MAX Plus), UV covers (Silostop® Supa Cova) and Silostop® gravel bags significantly improves the quality of silage around the edges and surface of the stack.

Figure 4: Silage inoculated with MANGIVA® Platinum showed lower levels of the mycotoxin Fumonisin B1. Drouin, P. Tremblay, J Renaud, J. Apper, E. (2020) Microbiology Open.

For more information, get in touch with your local Nutritech Area Manager.