Often pasture silages are made as a convenient way to manage a surplus, however there is so much more to gain from quality pasture silages.

Silage quality plays a significant role in economics and animal performance. Assuming you paid the same price to make poor quality grass silage as you did good quality grass silage, you end up paying significantly more per megajoule of metabolisable energy (MJME)and per kg of crude protein. This can have a massive impact on the economic value of that feed (Table 1).

Added to that are the reduced animal production and potential animal health consequences that will likely occur when consuming poor quality silage, meaning the true cost of that low quality silage is even greater.

Table 1

| Grass silage quality | $/tonne landed and after ensiling losses | DM % | $/kg DM | MJME/ kgDM | c/MJME | CP % | $/kg CP |

|---|---|---|---|---|---|---|---|

| Good | $100.00 | 35% | $0.29 | 11.0 | 2.60 | 16% | $1.79 |

| Poor | $100.00 | 35% | $0.29 | 9.5 | 3.01 | 11% | $2.60 |

The best way to protect and retain more valuable nutrients in grass and legume silages is to use high-quality, proven silage inoculants like MAGNIVA® range.

Adding a specific silage inoculant helps to reduce silage losses, especially in the early stages of fermentation. In these early stages, MJME can be lost and plant proteins can be broken down, resulting in poorer quality silage and a greater risk of undesirable micro-organisms spoiling the feed.

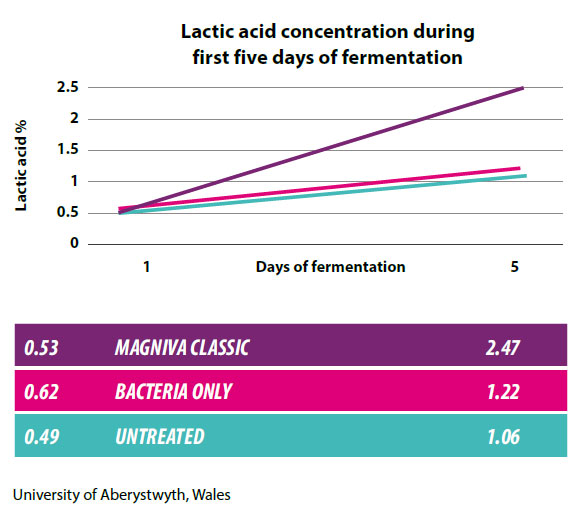

Figure 1: Lactic acid concentration during the first five days of fermentation.

New to the New Zealand market this season, MAGNIVA® Classic is unique in that it harnesses the power of two synergistic bacteria and two enzymes, which together work better than the bacteria on their own (Figure 1). The two specifically selected strains, P. pentosaceus NCIMB 12455 and L. plantarum CNCM MA 18/5U are chosen for their ability to drive the silage pH down to stop silage spoilage microorganisms taking hold.

When combined with β-Glucanase and Xylanase enzymes, silage sugars are quickly released from the forage, ensuring a quick fermentation and silage digestibility is increased. For grass and legume silages that are at risk of heating, farmers and contractors should consider switching to MAGNIVA® Platinum, for superior protection from yeasts and mould spoilage.

The team from Nutritech have a wealth of technical and practical silage knowledge, so make sure you get in touch if you need help choosing which inoculant is right for your silage situation.

A second important step in protecting grass silages is to use the Silostop® sealing system. Silostop® Orange and SiloStop® MAX Plus oxygen barrier technologies reduce silage losses in the top metre of stacks by almost half1. In addition to the reduced silage losses during storage, there is also a significant decrease in the percentage of inedible silage and an increase in the aerobic stability of that silage. This represents $7.20 worth of saved silage per m2 for grass silage or, if using later in the season, $15.30 for maize or whole crop cereal silage2.

- Wilkinson and Fenlon (2013). A meta-analysis comparing standard polyethylene and oxygen barrier film in terms of losses during storage and aerobic stability of silage. The Journal of the British Grassland Society.

- Assuming grass silage is valued at 25c/kgDM in the stack and has a density of 180kgDM/m3 . Maize or whole crop cereal silage is valued at 40c/kgDM in the stack and a density of 240kgDM/m3

Overall, producing quality grass silage makes sense from an economic, production and animal health perspective. For more information on making quality grass and legume silage this season, get in touch with your local Nutritech Area Manager.