In the past there was one inoculant for grass and legume silages, another for maize and wholecrop cereal silages. However, thanks to years of research, development and published trials by Lallemand Animal Nutrition, our understanding of what different silages need has changed over time. With more specific strains of bacteria, selected not just for their activity on their own but also their synergy with other bacteria, farmers and contractors can target exactly what each crop really needs.

Take for example three different pasture silages, outlined in Table 1 below. There are several considerations that factor into each silage challenge:

| Wet grass | ‘Normal’ grass | Drier grass | |

|---|---|---|---|

| Dry Matter | 27% DM | 35% DM | 42% DM |

| Crude Protein | 22% CP | 16% CP | 14% CP |

| Sugar content | Low | Moderate | High |

| Silage Challenge | Difficult to drop pH with so much water and protein in the silage. | Moderately difficult to drop pH. Heating challenge depends on sugar content, how much silage is removed from the stack face each day, maturity of the crop and chop length. | Significant heating challenge due to risk of trapped air and high sugar content. Also applies to baleage with high surface area exposed. |

| Silage Recommendation | MAGNIVA® Classic or Sil-All®4x4+ | MAGNIVA® Classic or Sil-All®4x4+ MAGNIVA® Platinum should be considered if slow face removal, mature crop or longer chop length. SiloStop® Orange high-oxygen barrier film also recommended to minimise surface losses. | MAGNIVA® Platinum SiloStop® Orange high-oxygen barrier film is strongly recommended. |

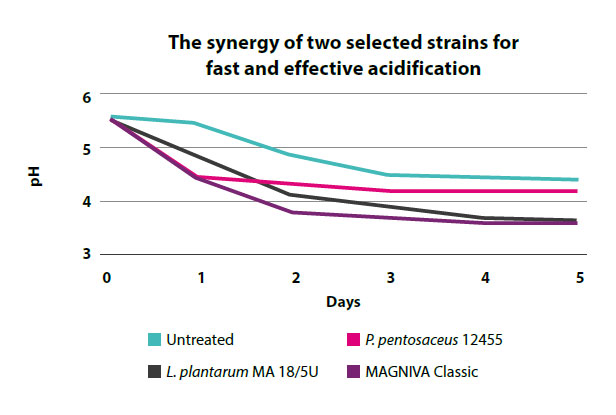

For those wetter silages, MAGNIVA® Classic works hard from the very beginning of fermentation, with a specific, fast-acting bacterium Pediococcus pentosaceous (strain #12455, which has an optimum pH of 6.0. This is much faster than the typically slow-fermenting Lactobacillus plantarum, which has a much lower optimum pH. The result? Fast, efficient fermentation, designed for wetter silages and those high in protein. To read more about a local farmer’s experience with MAGNIVA® Classic on wet silage, click here.

On the other hand, if silages are at risk of heating due to high sugar content, higher dry matter, longer chop length, more mature forages or the stack is at risk of poor compaction, it is worthwhile investing in MAGNIVA® Platinum.

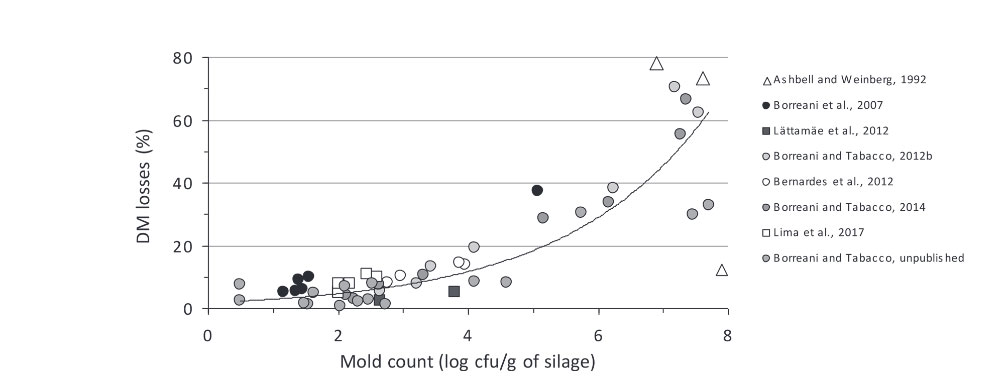

As shown in Figure 2 below, the more moulds we have, the higher our silage losses.

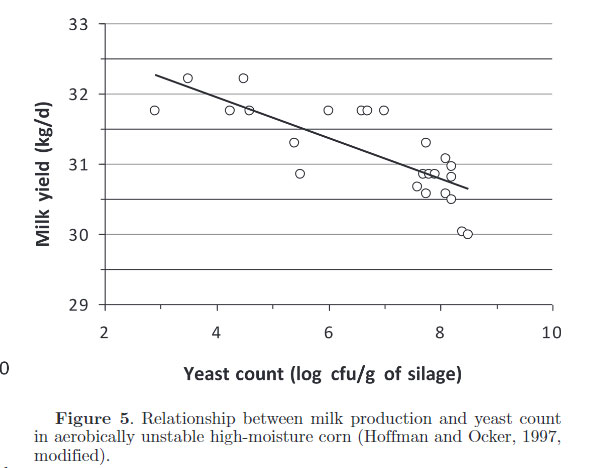

Further to the costly losses of silage, the more moulds we have the less milk that is produced from that silage (Figure 3), which highlights why clean, hygienic silage is so important for animal performance.

Figure 3: Relationship between milk production and yeast count in aerobically unstable silage (Hoffman and Ocker, 1997)

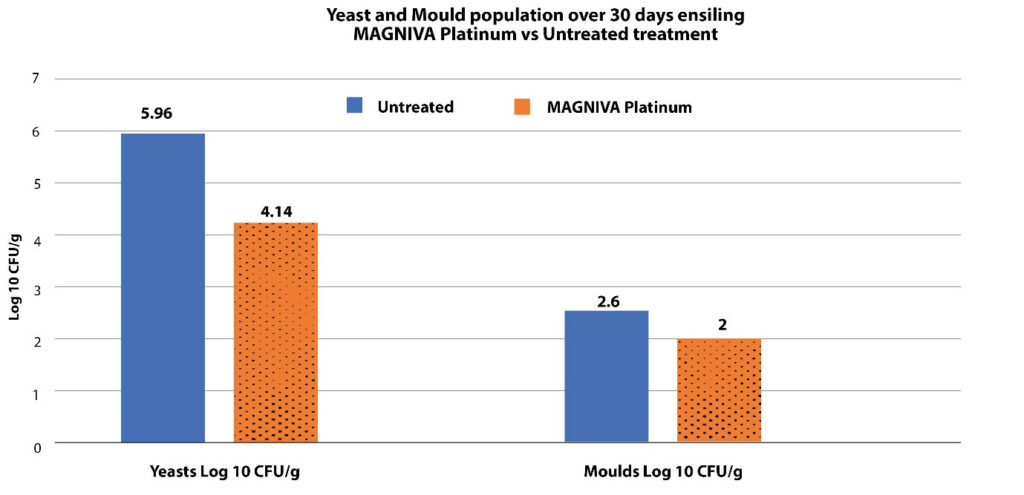

This is where some pasture and legume silages may be better protected with MAGNIVA® Platinum as it significantly reduces yeast and mould counts on grass and legume silages (internal Lallemand research). This then reduces heating losses and can extend aerobic stability (cool silage) from 2 days out to 6 days following exposure to air.

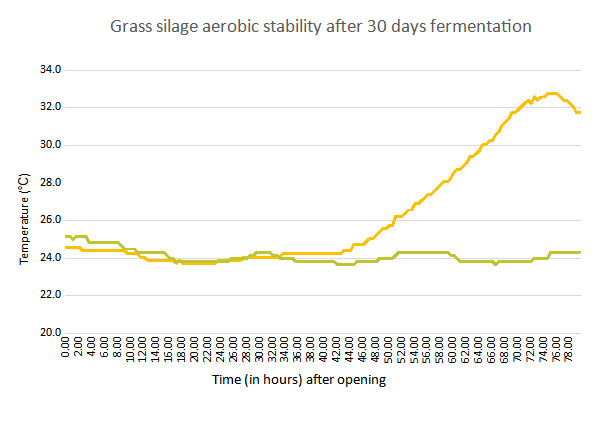

Figure 4: Control (untreated silage) in yellow, starting to heat two days after exposure to air, with MAGNIVA® Platinum treated silage (green) remaining cool after 6 days exposure to air.

Therefore, not all grass and legume silages should be treated equally! It is important to understand what is the most significant challenge that the silage will face, and treat it accordingly with the right, specific inoculant from the MAGNIVA® range.

For more help in choosing which inoculant is right for your pasture, lucerne or other green crop this season, get in touch with your local Nutritech Area Manager.